Undergoing regenerator repairs? Difficulty maintaining full production in an aging furnace?

Let our application engineers help you understand if the Cleanfire® ThruPortₑ™ burner is a good fit for your needs.

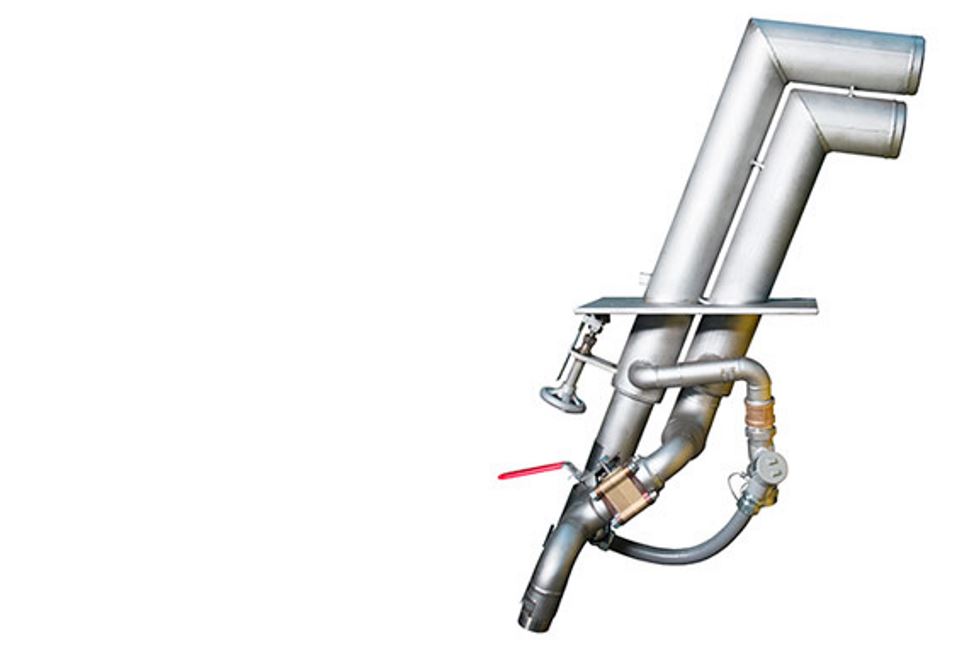

To avoid downtime during regenerator repairs or extend the life of an aging furnace, our ThruPortₑ burner can be easily installed through your existing furnace port to efficiently add heat and help maintain your desired production level—while delivering high efficiency and low NOₓ emissions. To do this, the burner takes advantage of several unique features:

Let our application engineers help you understand if the Cleanfire® ThruPortₑ™ burner is a good fit for your needs.