Key Benefits Include the Following:

- Ultra-fine particle size

- More uniform particle distribution

- Higher yields of particles in your target range

- Improved product quality due to minimal or no heat damage

- Less recycling and lower production costs

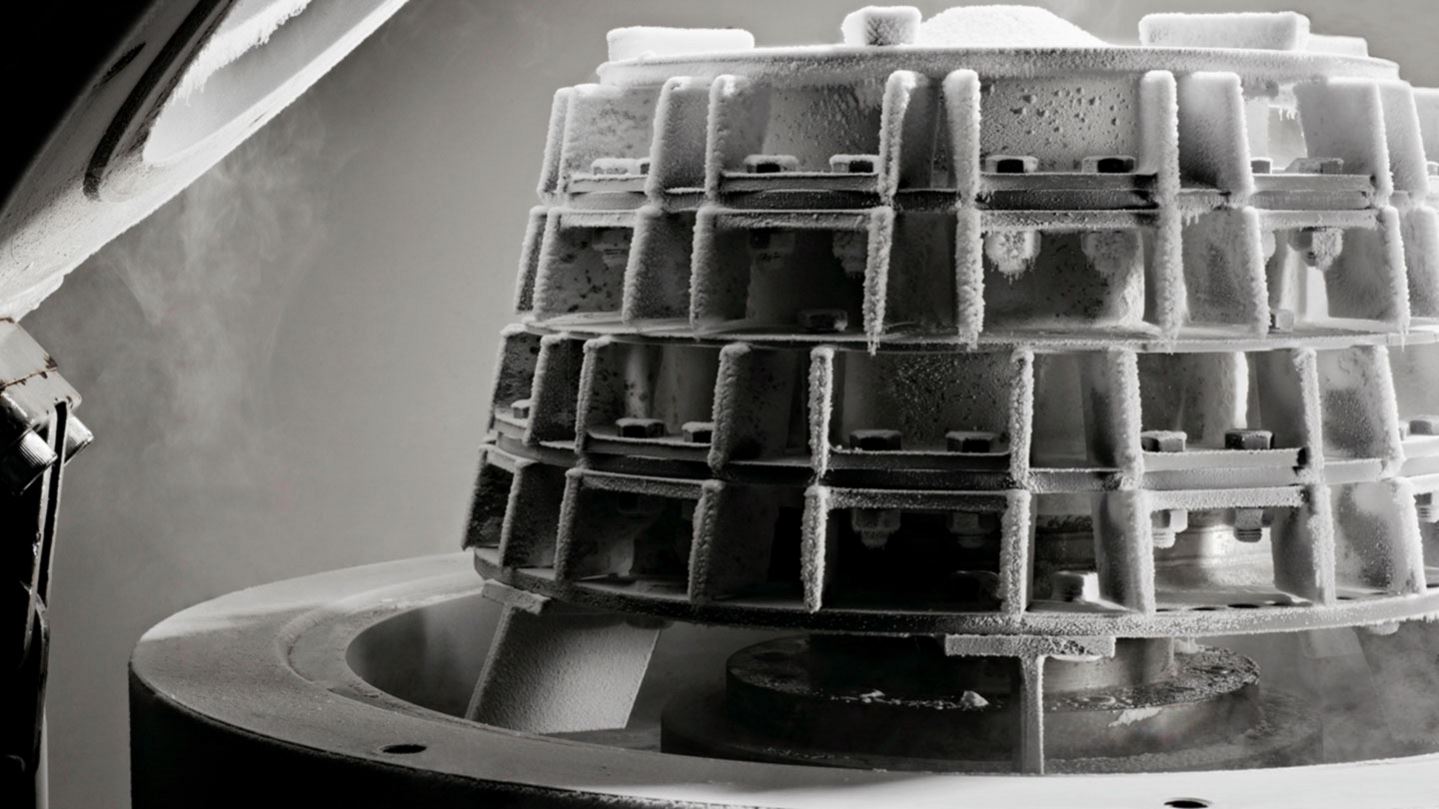

The PolarFit® Ultra-Fine-Grinding Mill

Using the cooling power of liquid nitrogen and multiple impact mechanisms, Air Products’ mill can help you achieve:

- Higher yields of particles in your target range, less recycling

- More uniform particle size, shape and distribution

- Fine to coarse particles from soft to hard materials

- Higher production rates

- Lower operating cost

Contact our engineers today

They can help determine which size reduction system configuration is best for your operation.

The Air Products Advantage

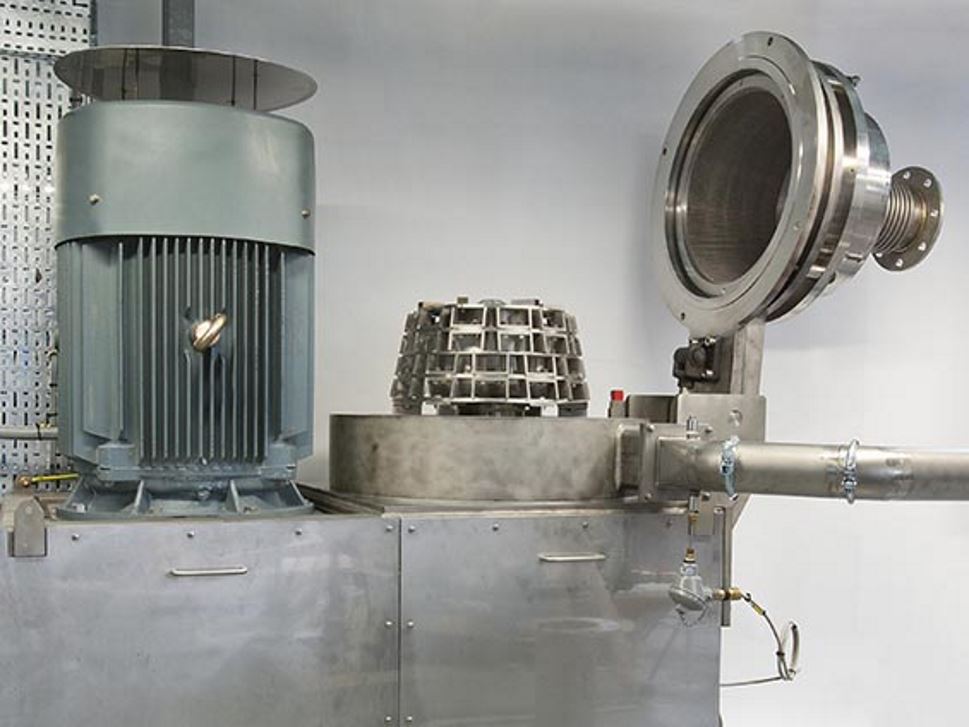

As a leader in cryogenic applications, we offer complete technical services from our experienced staff and fully equipped facilities:

- Feasibility and design through start-up and ongoing service

- Product testing using the ultra-fine-grinding mill at state-of-the-art trial facilities